-

garis produksi hydroforming tekanan tinggi internal

Ngabentuk tekanan tinggi internal, disebut oge hydroforming atanapi hidrolik ngabentuk, nyaéta prosés ngabentuk bahan anu ngagunakeun cair salaku medium ngabentuk sarta ngahontal tujuan ngabentuk bagian kerung ku ngadalikeun tekanan internal tur aliran bahan. Hydro Forming mangrupikeun jinis téknologi ngabentuk hidrolik. Ieu mangrupakeun prosés nu tube dipaké salaku billet, sarta billet tube dipencet kana rongga kapang pikeun ngabentuk workpiece diperlukeun ku nerapkeun ultra-tekanan cair jeung feed axial. Pikeun bagian kalawan sumbu melengkung, billet tube kudu pre-ngagulung kana bentuk bagian lajeng pressurized. Numutkeun jenis ngabentuk bagian, tekanan tinggi internal ngabentuk dibagi kana tilu kategori:

(1) ngurangan tube hydroforming;

(2) tube jero bending sumbu hydroforming;

(3) multi-pass tube-tekanan tinggi hydroforming. -

Pinuh otomatis Lambaran logam Stamping hidrolik Pencét Line Produksi pikeun otomotif

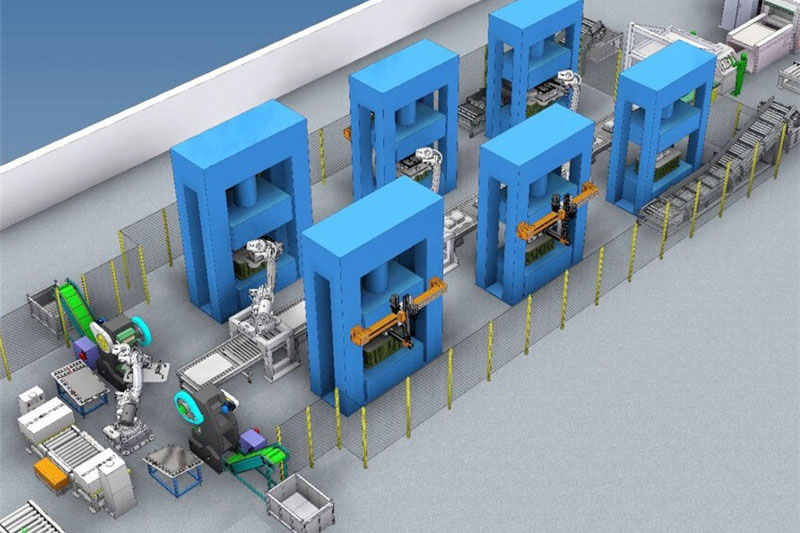

The Fully Automated Automotive Sheet metal Stamping Hydraulic Press Production Line revolutionizes nu tradisional dahar manual tur unloading garis assembly mesin tekanan ku incorporating leungeun robotic pikeun penanganan bahan otomatis tur fungsi deteksi. Garis produksi stroke kontinyu ieu ngamungkinkeun manufaktur calakan di pabrik stamping kalayan operasi lengkep unmanned sapanjang proses produksi.

Jalur produksi mangrupikeun solusi canggih anu dirancang pikeun nyegerkeun prosés manufaktur komponén otomotif. Ku ngagentos tenaga kerja manual sareng panangan robotic, jalur produksi ieu ngahontal nyoco otomatis sareng ngabongkar bahan, bari ogé ngalebetkeun kamampuan deteksi canggih. Ieu ngoperasikeun dina mode produksi stroke kontinyu, transforming pabrik stamping kana fasilitas manufaktur pinter.

-

Die Tryout Hidrolik Pencét pikeun Automotive Part Tooling

The Advanced Die Tryout Hydraulic Press, dikembangkeun ku JIANGDONG MACHINERY mangrupikeun vérsi anu ditingkatkeun tina lambar logam stamping pencét hidrolik tunggal. Dirancang khusus pikeun debugging kapang bagian otomotif, éta gaduh kamampuan adjustment stroke anu tepat. Kalayan akurasi fine-tuning nepi ka 0.05mm per stroke sarta sababaraha modus adjustment kaasup mékanis opat-titik adjustment, adjustment servo hidrolik, sarta tekanan-kurang gerakan handap, pencét hidrolik ieu nyadiakeun precision luar biasa tur kalenturan pikeun nguji kapang jeung validasi.

The Advanced Die Tryout Hydraulic Press mangrupikeun solusi canggih anu dirancang pikeun nyumponan sarat unik tina debugging kapang pikeun bagian otomotif. Diwangun dina dasar hiji-aksi lambar logam stamping pencét hidrolik, mesin inovatif ieu ngenalkeun kamampuhan adjustment stroke canggih pikeun mastikeun nguji tepat na validasi molds otomotif. Kalawan tilu modus adjustment béda sadia, operator boga kalenturan pikeun milih métode adjustment optimal pikeun kaperluan husus maranéhanana.

-

Maot Spotting hidrolik Pencét pikeun adjustment kapang precision

The Die Spotting Hydraulic Press nyaéta mesin husus dirancang pikeun ngolah kapang precision sarta adjustment. Ieu utamana cocog pikeun manufaktur sarta repairing sedeng pikeun molds stamping badag skala, nyadiakeun alignment kapang efisien, debugging akurat, sarta kamampuhan processing tepat. Pencét hidrolik ieu asalna dina dua bentuk struktural: nganggo atanapi henteu nganggo alat flipping kapang, gumantung kana kategori kapang sareng syarat prosés spotting. Kalawan precision kontrol stroke tinggi sarta kamampuhan stroke adjustable, pencét hidrolik nawarkeun tilu pilihan fine-tuning béda: mékanis opat-titik adjustment, adjustment servo hidrolik, sarta tekanan-kurang gerakan handap.

The Die Spotting Hydraulic Press mangrupikeun solusi téknologi canggih anu khusus direkayasa pikeun ngolah kapang sareng adjustment dina industri sapertos otomotif, aerospace, sareng manufaktur. Kontrol stroke anu tepat sareng kalenturan ngajantenkeun alat anu penting pikeun debugging kapang, alignment, sareng pamrosésan anu akurat.

-

Sedeng sareng plat kandel stamping sareng ngagambar garis produksi pencét hidrolik

Line Produksi Gambar Jero Lempeng Medium-Kandel kami diwangun ku lima pencét hidrolik, conveyors roller, sareng conveyor sabuk. Kalawan sistem robah kapang gancang na, garis produksi ieu nyandak gancang tur efisien kapang swapping. Éta sanggup achieving 5-hambalan ngabentuk jeung nransferkeun workpieces, ngurangan inténsitas tanaga gawé, sarta facilitating produksi efisien pakakas rumah tangga. Sakabéh garis produksi pinuh otomatis ngaliwatan integrasi hiji PLC jeung kontrol sentral, mastikeun produktivitas optimal.

Jalur Produksi mangrupikeun solusi canggih anu dirancang pikeun ngahasilkeun épisién komponén anu ditarik tina pelat sedeng-kandel. Ieu ngagabungkeun kakuatan sarta precision tina tekenan hidrolik jeung genah sistem penanganan bahan otomatis, hasilna ningkat produktivitas jeung ngurangan syarat tanaga gawé.

-

Single-aksi Lambaran logam Stamping hidrolik Pencét

Kami Single-Action Sheet Metal Stamping Hydraulic Press sayogi dina struktur opat kolom sareng pigura. Dilengkepan ku bantal hidrolik anu manjang ka handap, pencét ieu ngamungkinkeun rupa-rupa prosés sapertos manjang lembaran logam, motong (kalayan alat panyangga), bending, sareng flanging. Alatna gaduh sistem hidrolik sareng listrik mandiri, ngamungkinkeun pikeun panyesuaian sareng dua mode operasi: siklus kontinyu (semi-otomatis) sareng adjustment manual. Modeu operasi pencét kalebet silinder bantalan hidrolik teu tiasa dianggo, manjang, sareng manjang ngabalikeun, kalayan pilihan otomatis antara tekanan konstan sareng stroke pikeun unggal mode. Loba dipaké dina industri otomotif pikeun stamping komponén lambar logam ipis, éta utilizes manjang molds, punching mati, sarta molds rongga pikeun prosés kaasup manjang, punching, bending, trimming, sarta pagawean rupa. Aplikasina ogé ngalegaan ka aerospace, transportasi rel, mesin pertanian, alat-alat rumah tangga, sareng seueur widang sanésna.

-

Automobile Interior Pencét hidrolik Jeung Line Produksi

The Automobile Interior Pencét jeung Jalur Produksi dikembangkeun ku JIANGDONG MACHINERY utamana dipaké pikeun prosés molding komprési tiis tur panas komponén interior otomotif kayaning dashboards, karpét, ceilings, sarta korsi. Ieu bisa dilengkepan sistem pemanasan kayaning minyak termal atawa uap dumasar kana sarat prosés, babarengan jeung dahar otomatis tur unloading alat, bahan oven pemanasan, sarta alat vakum pikeun ngabentuk garis produksi pinuh otomatis.

-

Otomatis High-Speed Rupa-Blanking hidrolik Pencét Line pikeun komponén Metal

The Automatic High-Speed Fine-Blanking hydraulic Press Line dirancang pikeun prosés blanking precision komponén logam, husus catering kana produksi rupa-rupa bagian adjuster korsi otomotif kayaning rak, piring gear, adjusters sudut, kitu ogé komponén marake kawas ratchets, pawls, pelat adjuster, narik leungeun, push rod, piring beuteung, sarta rojongan piring. Saterusna, éta ogé mujarab pikeun manufaktur komponén dipaké dina seatbelts, kayaning basa ngaitkeun, cingcin gear jero, sarta pawls. Jalur produksi ieu diwangun ku pers hidrolik-blanking anu presisi tinggi, alat tuang otomatis tilu-dina-hiji, sareng sistem ngabongkar momotan otomatis. Ieu nawiskeun dahar otomatis, blanking otomatis, angkutan bagian otomatis, sarta fungsi motong runtah otomatis. Jalur produksi bisa ngahontal laju siklus 35-50spm.web, plat rojongan; Kancing, ring jero, ratchet, jsb.

-

Automobile Door Hemming hidrolik Pencét

The Automobile Door Hemming Hydraulic Press dirancang khusus pikeun prosés hemming sareng operasi blanking sareng motong panto mobil kénca sareng katuhu, tutup batang, sareng panutup mesin. Hal ieu dilengkepan sistem robah paeh gancang, sababaraha workstations movable dina sagala rupa wangun, mékanisme clamping paeh otomatis, sarta sistem pangakuan paeh.

-

garis produksi tilelep cai stainless steel

Garis produksi tilelep cai stainless steel mangrupikeun garis manufaktur otomatis anu kalebet prosés sapertos coil baja unwinding, motong, sareng stamping pikeun ngawangun tilelep. Jalur produksi ieu ngagunakeun robot pikeun ngagentos tenaga kerja manual, ngamungkinkeun parangkat otomatis manufaktur tilelep.

Jalur produksi tilelep cai stainless steel diwangun ku dua bagian utama: unit suplai bahan sareng unit stamping tilelep. Dua bagian ieu dihubungkeun ku unit transfer logistik, anu ngagampangkeun transportasi bahan antara aranjeunna. Unit suplai bahan ngawengku parabot kayaning coil unwinders, film laminators, flatteners, cutters, sarta stackers. Unit mindahkeun logistik diwangun ku carts mindahkeun, garis tumpukan bahan, sarta garis gudang palet kosong. Unit stamping ngandung opat prosés: motong sudut, manjang primér, manjang sekundér, trimming ujung, nu ngalibetkeun pamakéan tekenan hidrolik jeung automation robot.

Kapasitas produksi jalur ieu nyaéta 2 lembar per menit, kalayan kaluaran taunan sakitar 230,000 lembar.

-

The-speed tinggi Hot Stamping Line Produksi pikeun ultral High-Kakuatan Steel (Aluminium)

Jalur Produksi Stamping Panas-speed tinggi pikeun Ultral High-Strength Steel (Aluminium) mangrupikeun solusi manufaktur canggih pikeun ngahasilkeun bagian-bagian awak otomotif anu kompleks nganggo téknik hot stamping. Kalayan fitur sapertos nyoco bahan gancang, pencét hidrolik stamping panas gancang, kapang cai tiis, sistem dimeunangkeun bahan otomatis, sareng pilihan pamrosésan salajengna sapertos shot blasting, motong laser, atanapi sistem trimming sareng blanking otomatis, jalur produksi ieu nawiskeun kinerja sareng efisiensi anu luar biasa.

-

Ultra High Kakuatan Steel (Aluminium) Otomatis Tiis motong / Blanking Line Produksi

The Ultra High Strength Steel (Aluminium) Otomatis Cold Cutting Line Produksi mangrupakeun state-of-nu-seni sistem otomatis dirancang pikeun pos-processing baja-kakuatan tinggi atawa aluminium sanggeus stamping panas. Ieu fungsi minangka hiji gaganti efisien keur parabot motong laser tradisional. Jalur produksi ieu diwangun ku dua pencét hidrolik sareng alat motong, tilu panangan robotic, sistem ngamuat sareng ngabongkar muatan otomatis, sareng sistem transmisi anu dipercaya. Kalayan kamampuan otomatisasina, jalur produksi ieu ngagampangkeun prosés manufaktur kontinyu sareng volume tinggi.

The Ultra High Strength Steel (Aluminium) Otomatis Cold Cutting Line Produksi ieu husus dimekarkeun pikeun pos-processing tina-kakuatan tinggi baja atawa bahan aluminium handap prosés stamping panas. Éta nyayogikeun solusi anu dipercaya pikeun ngagentos padika motong laser tradisional anu pajeulit sareng nyéépkeun waktos. Garis produksi ieu ngagabungkeun téknologi canggih, alat precision, sareng otomatisasi pikeun ngahontal manufaktur anu lancar sareng efisien.